How to make a sniper rifle. Part 7: Mounting a side rail on the Mosin Nagant

As described in the previous post, the best - and the priciest, and the hardest to

install - scope mount is the Dragunov side rail.

This post describes how to install it.

Preserving the original rifle

Most Mosin Nagant rifles made during WWII in Russia have no

historical value. Majority were rebuilt in Russian arsenals after the war from a

smorgasbord of non-matching parts, sealed in cosmoline, and put away. You can

safely treat these rifles as a LEGO set - it is OK to permanently modify

it.

And modified it will be - the stock will have to be dremeled to

create an opening for the side rail, and the bolt handle will be

replaced.

If, however, your rifle has matching numbers (especially if

bayonet number matches as well!), have been made before the war, and is in

excellent shape, you might want to buy extra parts instead of modifying the

originals. Preserving original stock and bolt body would allow you to restore

your rifle to its exact original shape easily.

Note: I think modifying a

pre-revolutionary Mosin Nagants in any way, shape, or form is an act of pure

barbarism. There are not so many of them left! If you are a lucky owner of a

pre-1917 rifle, and want one with the scope, please let me know and I will be

happy to trade a finished one - with the rail installed, and bolt bent - for it.

Or two unfinished ones :-).

If you want to preserve the original parts,

you will need to procure the parts you will modify - the stock and the bolt body

- separately. The stock is easy to buy, for example, http://www.buymilsurp.com/ has a whole lot

of them in various conditions. Since you can reuse the metallic part, you will

have to refinish the stock (see below), and you do not need the handguard (it

only makes the rifle less accurate), you can buy a cheaper part. For example, as

of this writing, there were plenty of very acceptable variants in the $25

range.

On the other hand, procuring the bolt body is very, very hard. You

only need the bolt body, not the entire bolt. In fact, because you probably do

not have a headspace gauge, you will need to reuse the rest of the components of

the original bolt because it matches the rifle (to learn more about headspace,

and what can go wrong if you don't pay attention to it, read this: http://www.surplusrifle.com/shooting/headspace/index.asp).

Bolt body is the part to which the handle is attached.

There currently is not a good place

where bolts or bolt bodies can be purchased. The cheapest, but an unreliable

source is your local gun show - there typically would be a few available for

$10-$12. Unless you are in Seattle area, because I bought up every one that was

available locally :-).

An unknown type of the already bent bolt body is

sold here: http://www.tngunparts.com/m9130.htm.

See below (in the Bolt Body section) for precaution - the bolt handle

needs to be replaced, not just bent.

Failing that, look for ads for

surplus rifle parts in Shotgun News, there usually is a place or two where you

can get complete bolts for $25-$40 a piece. I bought quite a few

there.

Check http://www.ebay.com/ or

http://www.auctionarms.com/, the parts

occasionally show up there.

Boltman (http://www.mosinnagant.net/Boltman/Boltman.html)

sometimes has them in stock, but more often he does not. If he does, the price

quoted on the page above ($55 for the whole thing) is very, very

attractive.

Failing all that, you can buy a rifle in a very poor shape

and cannibalize it. If you have a C&R license, you can often find them on

the Internet for less than $40.

Failing everything else, the bolt bodies

can be purchased for $34 from Numrich store at http://www.gunpartscorp.com/catalog/Products.aspx?catid=3258.

Yes, this is ridiculous considering that the price of a gun was

~$100.

Remember the headspace, however - do not move the entire bolt from

rifle to rifle!

Project inventory

You will need the following things for the project.

(1) The rail from http://www.kalinkaoptics.com/. $25 plus

a ridiculous shipping price. Tough luck: this is the only place where this

particular component can be found. On their web site, Browse Category ->

Firearm Accessories -> Side Rails (http://www.kalinkaoptics.com/firearm-accessories/side-rails.html).

Be careful not to buy the undrilled

side rail for $15 - it is too thin and will not stick enough to protrude

above the stock surface.

(2) "Original BP-02 SVD, PSL, Tigr Low Profile

Centered Side Mount to Weaver Rail" from http://www.kalinkaoptics.com/, $53

(plus the above "arm and leg" for shipping. Combine with (1) and it will be

slightly less offensive). "Low profile" part is very important. This can be

found in Browse Category -> Mounts -> SVD, Tigr, Romak-3 (http://www.kalinkaoptics.com/mounts/svd-psl-tigr-romak-3.html).

(3) Stock that you will feel OK

modifying (see "Preserving the original rifle" above).

(4) Bolt body that

you will feel OK modifying (see "Preserving the original rifle"

above).

(5) Drill bit #11, drill bit #21, 10-32 tap, T-wrench to hold the

tap, and 2 10-32 x 1/2" screws. This is available in the local hardware store

(for example, ACE). Get the ones that are the best quality, designed for

hardened steel.

(6) Cutting oil.

This is a bit hard to find, but I tracked it down in Lowe's and in ACE. Home

Depot does not have it.

(7) Drill press. Local hardware store,

$120-$180.

(8) Drill press vise. Home Depot,

$16. A few large matching bolts, nuts, and washers to fix it to the

drill press table, same source.

(9) Small bulls eye level. Home Depot.

(10) Paint stripper, for example, Citristrip (http://citristrip.com/). Sand paper (coarse

and fine), steel wool (fine). Two brushes. Gloves, paper towels, 2 wood blocks,

old newspapers. Local hardware store.

(11) Wood stain of your choice. You

should defer picking the color until you have stripped the stock of its current

paint.

(12) A rotary tool like Dremel.

(13) A gun vise or an inexpensive shooting rest. http://www.midwayusa.com/, $20-$60,

depending on whether you want to have something you can use for shooting, or

just mounting the gun for cleaning and scope alignment.

(14) A laser boresighter. http://www.midwayusa.com/. There is no

picture here because I really cannot recommend any particular model - the choice

is between an expensive and crappy one ($150 LaserLyte Kryptonyte Green Laser

Boresighter 22 to 75 Caliber), and a less expensive but equally crappy one ($30

Sightmark Laser Bore Sight 243, 308 Winchester, 260, 7mm-08 Remington).

Price/performance of the Sightmark is better. The above-referenced caliber (243)

works for 7.62x54r, although the bolt does not close. This is OK, the bolt does

not close in 308 rifles either.

Bolt body

To work with

any scope mount other than the scout mount, the bolt handle needs to be turned

down. This is because when the bolt is open, it's handle sticks upwards and

interferes with the scope. There are several ways this can be accomplished.

First, there is an ATI bolt handle kit that costs around $20 on eBay and

contains the replacement handle, the drill bit, the tap, and the screw. The

result does not look amazing, and requires notching the stock because the handle

extends directly down when the bolt is closed.

The picture below looks nicer than the reality.

As of this writing, a bolt body with

the handle turned down can be bought from here: http://www.tngunparts.com/m9130.htm for

$54. I have not used them, so I do not know how exactly is the bent handle

manufactured,. Sometimes they simply bend the handle down without adding to the

length of it. The result is not that good, there simply is not enough

handle to grab it when opening and closing the action:

(the part above is available

here, http://www.gunpartscorp.com/catalog/Detail.aspx?pid=291700&catid=3258 for

$34)

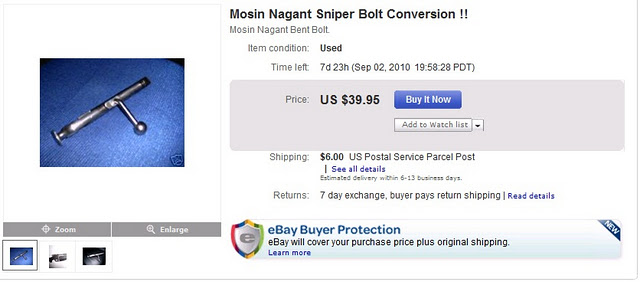

eBay has a number of people sell bolt bending as a service:

you mail them your body, they modify the handle for you, and mail it back. I

used Marvin Burrows (eBay: mellbee) several times, and he does excellent job for

around $46, including shipping. This is his eBay ad:

And this is the result:

The turnaround time is about

2 weeks including the mailing time.

If you are really

adventurous, you can try doing it yourself using the instructions here: http://www.gswagner.com/mosin-nagant/bolt/mnbolt.html

...or here:

http://www.opticstalk.com/topic12364.html.

Side Rail

This is the "mechanical" part of the

project. You will need to drill and tap 2 holes in the receiver to attach the

side rail.

To do this, you need to attach the side rail to the

receiver temporarily to drill the very first hole. It goes on the left part of

the receiver so that its top is close to flush with the opening in the action.

This time I suggest you remove the

trigger group by unscrewing the single screw that holds it on the receiver.

Mounting the receiver in the vise is hard as it is, without extra parts sticking

out.

Before you mount the receiver, ensure that the drill table

is horizontal by using a level. You will need this to align the receiver surface

to be perfectly horizontal afterwards.

Place the rail in the side

of the receiver. I do not know if there is "the" right spot. The receiver is

curved, and on all 3 rifles on which I put the side rail the scope ended up

pointing up and to the left relative to the barrel axis. This is OK: the problem

will be corrected by shimming the mounting bracket. See the couple of pictures

above for approximately right location.

The legs on the rail

should obviously hug the receiver and not hang out through the action's opening.

Fix the side rail in place. You can use either a very small clamp, or

wrap it tightly using electrical or duct tape. Make sure that neither cover the

opening which you will drill.

Plug the chamber with a tight wad of

paper towel to ensure that the metallic debris from drilling does not end up in

the chamber or the barrel.

Place the drill table vise on the

drill table. Do not yet attach it with the bolts. Place the receiver on the

vise, tighten the vise as little as necessary so that the receiver does not

slide. Guide the system so that the hole in the side rail is approximately below

the drill's chuck, and at the same time all four of the mounting openings in the

vise intersect with the mounting openings on the drill table.

Adjust the drill table to a height where the drill bit can be lowered

sufficiently to drill through the receiver.

Put the bolts through the

mounting holes. Use the washers on both sides, and screw them down so that the

whole system can move about with some friction. Now place the bulls eye level on

the side rail, reopen the vise jaws just a little bit so that receiver can be

reoriented, and move it slightly so that the bubble of air in the level is right

in the center. Reclose the vise jaws and tighten them, while monitoring the

bubble - when jaws are closed the receiver might shift and the leveling action

will have to be repeated.

Now that the system is aligned

horizontally, put the larger drill bit in the chuck. Tighten. Do not turn the

drill on yet, but lower the chuck to see where it would touch the metal. By

moving the vise slightly ensure that the drill bit goes exactly through the hole

in the side rail. The larger drill bit should fit tightly through that hole.

When it's in, rotate it around to make sure that the system is perfectly aligned

and the drill bit does not scrape the metal of the side rail.

Tighten the bolts that fix the vise on the drill table. Lower the chuck

again to make sure the position did not shift. Rotate it around again.

Put the eye protection on, turn on the drill and lower the larger

bit just enough to make a small crater, just the diameter of the drill but not

deeper than necessary, on the steel of the receiver. Raise the chuck and replace

the drill bit with the smaller one. Lower the chuck to ensure that the system is

still aligned. The drill bit should touch the metal right in the middle of the

crater left by the bigger drill.

If the drill has an adjustable RPM, set

it to medium low (800-1200). Place a drop of the cutting oil on the receiver

where it will be drilled. Note that cutting oils are toxic, do not let it

anywhere near your exposed skin. Use gloves!

Drill slowly, raising the

chuck to clear the metal debris out of the hole often. Do not apply a force that

is more than 20lb (100N). This is very important, or the drill bit can break and

stick in the hole, and it might be impossible to remove it! When the hole is

drilled though, remove the receiver from the vise, and remove the side rail

from the receiver. Using paper towel (and gloves!) clean all metal debris from

the receiver.

Put another drop of cutting oil (gloves!) on the tap.

Rotate it and guide it in the hole, maintaining perpendicular angle to the

receiver. Go lightly, reversing the direction, cleaning the debris and reoiling

frequently. A broken tap is a disaster - it is made of a hard alloy and if

broken is next to impossible to remove.

When the thread is cut

(the widest part of the tap is through the hole), remove the tap, clean the

receiver and the new thread using paper towels. You can now screw the side rail

to the receiver using the newly made hole and one of the screws, and repeat the

process for the next hole.

Useful hint: when tapping the second

hole, keep the side rail in place (but clean the drilling debris out!), it will

help guide the tap.

Stock

This is the last part of the

project. Now that we have a rail on the side of the receiver, the stock will not

fit and a cut out needs to be made to accommodate the part that is sticking out.

Also, the height of the side rail is somewhat smaller than the thickness of the

stock, so a small layer of wood needs to be removed from the left side of the

stock so that the rail is exposed enough.

Because quite a bit of finish

will be removed to accommodate the rail, we will need to refinish the stock. If

you have done this before, just go with what you know, not what I write here. I

am a complete novice to wood finishing, and the results I personally achieved

are functional, but not beautiful.

First, use the paint remover to get

the current finish off. You will need a brush, a paint stripper, steel wool and

sand paper for this.

Citristrip is a paint stripper that can be used

indoors, other must be used outside. Make sure that the weather is right! Vast

majority of them are health hazard so be cautious and read the instructions

before starting. I found that a combination of Citristrip followed by the

classic stain remover works well.

Although most of the paint/wax/whatever

it is will come off, some coloring will still remain.

You can probably get closer to

clean wood by sanding it off with sandpaper.

After you got as much

previous stain off as you think is practical, pick the stain that will (1)

survive outdoors, and (2) will either match the previous

stain closely or be dark enough to cover the remaining traces of the

older stain. I chose the later route, so that's what you see in the

pictures.

Place the barrel in the receiver and mark the places where the

stock interferes with the side rail. Using the rotary tool and the sanding

band...

...remove the side of the stock about 1/2 of the width

of the rail. Use the cutting attachment...

...to take care of the corners. Replace the receiver to

see how much the opening needs to be deepened. Keep doing this until the screwed

down receiver can go into the stock all the way and the side rail still does not

touch the stock.

Now take the scope or the mounting bracket and try to

slide it onto the rail. You will see that the side of the stock prevents it from

engaging. Again, using the rotary tool keep removing thin layers of the side

until the scope mount can slide onto the rail.

Take a look at the picture

below and note the depression cut out on the stock to accommodate the

externalities of the scope mount.

After the barreled receiver fits

(do not forget to screw it in and tighten the screws before ensuring that the

rail does not touch the stock), and the scope mounting bracket fits on the rail,

you are ready to apply the stain to the stock.

Disassemble the rifle back. Using the instructions for your stain and working in an open space (the

fumes are toxic!), apply a coat of stain, let it dry, then repeat twice,

applying the total of 3 layers.

After the stain dries completely (this will take a day), reassemble the rifle fully.

Adjusting the scope mount

As I said above, the side rail will not be precisely aligned with the barrel axis. In all

my mounts "out of the box" the scope will point high and to the left. This

misalignment may or may not be correctable by the scope's internal adjustment

mechanism, but it is much better to instead adjust the scope mount so that the

scope's natural axis is in alignment with the barrel.

There are a few reasons for aligning the mount instead of adjusting the scope.

First, the mount is probably pointing high. Even if you can adjust the elevation on the

scope, your scope will be close to out of the adjustment range pointing down. So

when you would want to move it down for shooting at 200/300 meters, it is very

likely that you will not be able to do it because scope's adjustment range will

already have been used to compensate for the rail.

Second, scopes near the edge of their adjustment ranges tend to not keep zero as well as they do

when they are centered.

Adjusting the Dragunov-type mount is actually

very easy. The bracket's top rail is attached to the middle part by two screws,

and the middle part attaches to the part that goes on the side rail with 4

screws. The windage (horizontal) adjustment is achieved by putting shims between

the middle and the bottom part, and the vertical adjustment is achieved by

shimming the rail.

I use aluminum strips from soda cans for shims - they

can be stacked to achieve exactly the necessary thickness.

Attach the scope to the mount.

Ensure that the scope's optical axis is centered. To do this, loosen the scope

in the rings and rotate it while observing the cross hairs through the eyepiece.

If the scope axis is centered, the impact point will be the same while the scope

rotates. Use windage and elevation adjustments to center the scope. When the

scope is centered, tighten the rings.

Turn the laser boresighter on

and put it into the chamber. Put the gun in a vise and point it to the wall some

distance away (10 meters or more, depending on the minimum distance at which

your scope still focuses). Note where the scope's cross hairs are, relative to

the laser beam.

Turn the boresighter off. You will need to make

several measurements, and the batteries are only good for minutes (despite what

the instructions claim).

Disassemble the scope mount, and measure

the sizes of the holes and distances between them.

Cut off several rectangular pieces of aluminum foil from the side of a soda can.

Initially make them much larger than is really needed. For the top shims you

will need to drill one big and one very small hole next to each other. For the

bottom shim, you will need two holes of the same size. The drill press will help

here.

It is easier to drill the holes when multiple layers of the

aluminum are bunched together. After the holes are done (plan to waste a few

pieces to practice) you can cut around them to size.

Add a few shim

pieces, reassemble the mount and replace the scope. Turn the laser boresighter

on and observe the new impact point.

The goal is to have the cross hairs

about 1"-1.5" ABOVE the laser mark at 10 meters. The actual scope axis is about

2" above the barrel axis, but you want to make the centered scope point a little

bit DOWN so that it does not run out of DOWNWARD alignment when shooting at

distances beyond 100 meters (to track the bullet trajectory the scope gets

turned down as the target is farther away).

You will have to do a few

passes to get the scope almost right. It does not have to be completely on

target - the last final touches are worked out using the scope's internal

adjustment mechanisms. Do not spend too much time on it until you get to the

range though - the accuracy of the laser boresighter is only within 10" at a 100

meters, if even that. It will get you on paper and you will use the scope's

controls to get on target from there.

Contents

- Introduction

- Buying

- Cleaning

- Disassembly

- Accurizing

- Selecting a scope mount

- Mounting a side rail

- At the range